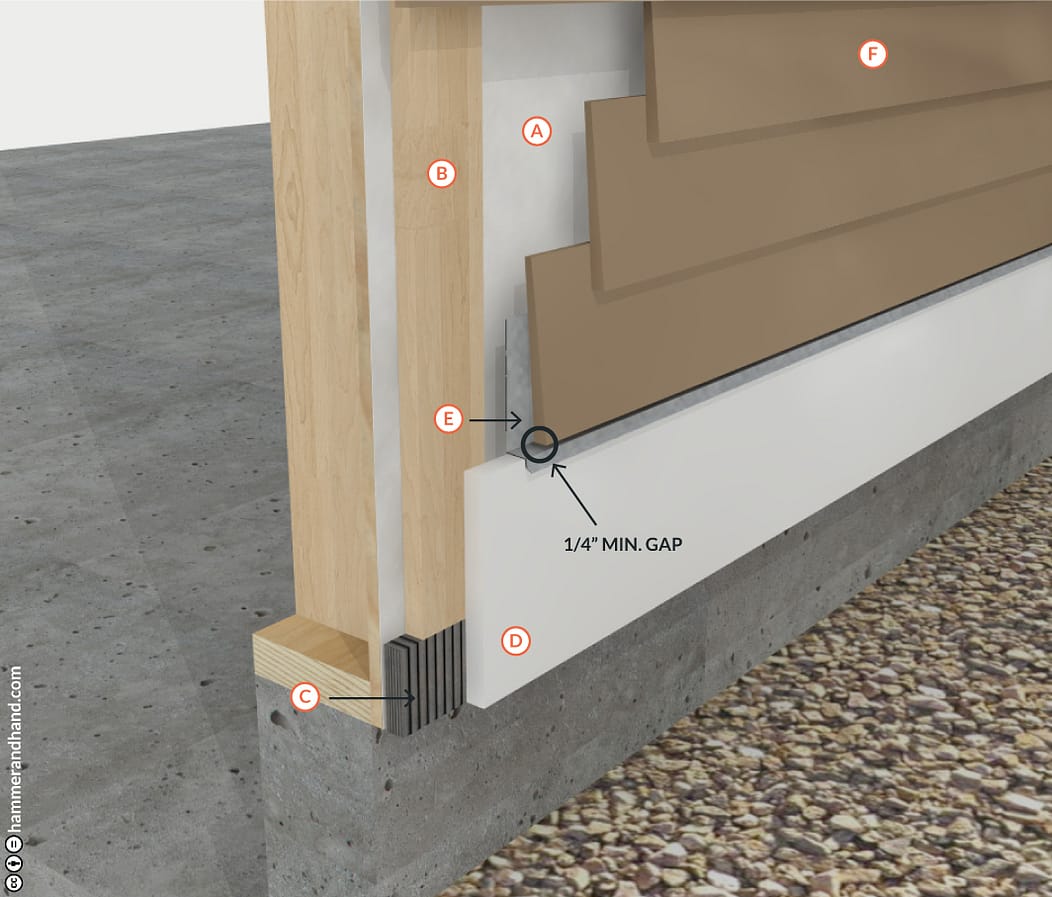

A. WRB (WATER-RESISTIVE BARRIER)

B. FURRING

C. COR-A-VENT SV-5

B. FURRING

C. COR-A-VENT SV-5

D. WATER TABLE

E. FLASHING

F. CLADDING

E. FLASHING

F. CLADDING

- Layer on WRB.

- Seal sheathing to stem wall with Joint & Seam filler.

- Install vertical furring to correspond with the framing method (aligned with vertical framing members).

- Use untreated 1×4 furring.

- Attach a continuous strip of Cor-A-Vent SV-5 insect blocker at bottom of furring.

- Attach water table to furring.

- Install flashing above water table.

- Install siding to complete the rain screen.